Budada Birta ah ee Sifaynta Polymer

Taariikhda Horumarinta Budada Birta ee Warbaahinta Shaandhaynta Polymer

Boomerka sare ee PET PA PP ee la shubay wuxuu u baahan yahay in la sifeeyo ka hor inta aan fibre kiimikaad la wareegin si meesha looga saaro wasakhda iyo walxaha jel ee ku dhex milmay dhalaalka si looga hortago xidhidhiyaha daloolka spinneret, hagaajinta tayada fiilada PET PA, sida dunta POY FDY ;marka polymer-ka dhalaalku uu dhex maro lakabka muraayadda lafdhabarta, iska caabin ayaa la abuuraa, si ay u dhalaalashadu u dhaliso kulayl, heerkulku kor u kaco, sifooyinka rheological ee dhalaalka ayaa la hagaajiyaa.Isla mar ahaantaana, dhalaalka ayaa si buuxda isku dhafan si looga hortago kala duwanaanshaha viscosity ee u dhexeeya dhalaalka;dhalaalidda waxaa si siman loo qaybiyaa dalool kasta oo yar oo spinneret ah;iyadoo la kordhinayo wakhtiga isticmaalka shaandhada baakidhka lafdhabarta, wasakhda ku jirta lakabka shaandhada xidhmada mesh ayaa kordhin doonta, cadaadiska shirkuna si tartiib tartiib ah ayuu u kordhi doonaa.Xawaaraha korodhka cadaadiska waa mid degdeg ah, iyo nolosha adeegga shirku waa mid gaaban.Marka shirku u kaco cadaadis gaar ah, waxaa lagama maarmaan ah in la beddelo golaha waqtigeeda, haddii kale, bamka cabbiraadda waa la jajabiyaa, ama spinneret waa qallafsan yahay, ama dheecaan ayaa dhacaya.

Xulashada qaybaha shaandhada ku habboon ayaa aad muhiim ugu ah wareegga fiber-ka synthetic, iyo warbaahinta shaandhada ku habboon ayaa si gaar ah muhiim u ah.Inta lagu jiro geedi socodka horumarinta wareega, sidoo kale waa habka lagu helo dhexdhexaad shaandhada xiirta ugu fiican.Alaabooyin badan oo shaandhada la yaqaan waxaa ka mid ah ciidda badda, biraha xiirashada, kuul quraarad ah, taarikada birta daloolsan, iyo qaybo bir ah oo qaab aan caadi ahayn u qaabaysan.

Marka laga soo tago inay tahay mid aan qaali ahayn, dhexdhexaadinta shaandhaynta ugu habboon waa inay lahaataa oo waa inay ilaalisaa porosity sare ee cadaadiska la kulma inta lagu jiro sifaynta polymer dhalaalaysa.Si loo ilaaliyo porosity sare, sariir ka mid ah qaybaha ugu badan ee polymers kulul ayaa u janjeera inay sameeyaan jel kaas oo ku urura oo yareeya waxtarka sifaynta ee warbaahinta shaandhada.Haddaba, walxaha shaandhaynta birta ah waa in aanay kicin ama haddii kale wax ku biirin samaynta jel.

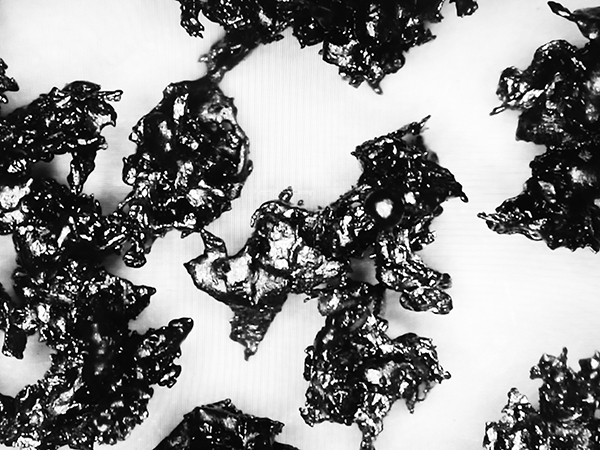

Aad bay u diyaarsan tahay in la helo ciidda badda, laakiin aad bay u jajaban tahay natiijada in korriinka qaybo yaryar ay u janjeeraan inay xannibaan xididdada lafdhabarta.Intaa waxaa dheer, aagga gaarka ah ee ciidda badeedku aad buu u yar yahay oo waa ka yar yahay boqolleyda porosity ee mugga shaandhada baakad kasta, sidaas darteed cadaadiska baakadu waa inuu si aad ah u kordhaa.Budada birta ah ee lagu diyaariyey shuruudo gaar ah waxay muujinaysaa dusha aan caadi ahayn taas oo u dhiganta cufnaanta hoose ee muuqata, waxay u egtahay inay kor u qaaddo waxtarkeeda sifaynta;cadaadiska hawlgalka, waxay muujinaysaa labadaba cufnaanta muuqata waxayna kor u qaadaysaa caabbinta cadaadiska si loo sifeeyo waxtarka ugu wanaagsan oo leh wax yar ama aan lahayn qallafsanaan iyo burbur.

Xulashada budada ah ee birta ah ee FUTAI

FUTAI waxay soo jeedinaysaa F-01 ciid bir ah oo taxane ah oo loogu talagalay polyester POY FDY filament oo u wareegaysa sidii warbaahinta sifaynta dhaqaalaha;Si loo hagaajiyo tayada dunta, FUTAI waxay ku talinaysaa S-03, xoog farsamo oo sarreeya iyo budada birta xasaasiga ah ee oksaydhisku yar;Codsiga cadaadiska bilowga ah ee sare, S-04 waa doorasho la jecel yahay oo loogu talagalay iska caabbinta la xoojiyey ee isku-buufinta, si aan macquul ahayn u dhalaalaysa polymer, gaar ahaan codsiga wareegga PA filament.

Nooca budada ah ee birta ah

| Nooca | Fe(%) | Ni(%) | Cr(%) | Mn(%) | Si(%) | Mo(%) | C (%) | Codsiyada |

| F-01 | Bal. | Ugu badnaan.0.6 | 16-18 | Max.1.0 | 1.0-4.0 | - | Ugu badnaan.0.12 | Budada birta dhaqaalaha |

| S-03 | Bal. | 6-12 | 16-22 | Max.1.0 | 0.6-3.5 | Max.3.0 | Max.0.12 | Warbaahinta caadiga ah |

| S-04 | Bal. | Max.0.6 | 33-37 | Max.1.0 | 2-4 | - | Max.0.12 | Warbaahin heersare ah |

Faa'iidooyinka

1. Xoogga farsamada sare.

2. Iska caabin cufan oo sarreeya.

3. Habacsanaan sare.

4. Porosity sare.

5. Si xoog leh oo aan firfircoonayn si ay u dhalaaliso polymer.

6. Cimriga dheer ee xirmada lafdhabarta.

7. Tayada dunta wanaagsan.

Cabirka Mesh-ga la heli karo iyo Astaantiisa Jireed

Marka la farsameynayo fiilo-wareejinta, sida POY iyo FDY dunni, muhiimada ugu badan waa in la isku daro dhawr cabbir oo budo ah oo kala duwan si loo helo saamaynta sifaynta ugu fiican.FUTAI waxay siin kartaa dhammaan macaamiisha xulashada ugu wanaagsan ee cabbirrada mesh iyadoo lagu saleynayo aqoontayada sida budada birta ah ee aan nadiifka ahayn iyo khibrado qani ah oo ku saabsan wax soo saarka fiber-ka synthetic, si ay macaamiishu si buuxda uga faa'iidaystaan faa'iidooyinka ciidda birta ah, kordhiyaan cimriga xirmada lafdhabarta oo gaaro tayada wanaagsan ee dunta fiilooyinka.

Aakhiro waa liiska cabbirrada la heli karo iyadoo loo eegayo ISO 4497 INTERNATION STANDARD ee budada birta ah.Cabbir kasta oo kale ayaa la soo saari karaa marka la codsado.

| Cabbirkamicron | Cabbirkamesh | Cufnaanta muuqatag/cm3 | Taabo cufnaantag/cm3 | Porosity % |

| 850/2000 | 10/20 | 1.45 | 1.95 | 75 |

| 500/850 | 20/30 | 1.55 | 2.10 | 73 |

| 350/500 | 30/40 | 1.60 | 2.10 | 71 |

| 250/350 | 40/60 | 1.65 | 2.60 | 67 |

| 180/250 | 60/80 | 1.80 | 2.70 | 65 |

| 150/180 | 80/100 | 2.00 | 2.90 | 62 |

| 125/150 | 100/120 | 2.22 | 3.10 | 58 |

| 90/125 | 120/170 | 2.50 | 3.20 | 56 |