Shaandhaynta caleenta saxanka loogu talagalay Shaandhaynta Filimada Polymer

Sharaxaada Alaabta

Xalka shaandhaynta FUTAI ee habka filimka polyesterka ayaa inta badan ka faa'iidaysta tignoolajiyada sare ee lahaanshaha si kor loogu qaado joogtaynta badeecada, kor loogu qaado tayada, loona yareeyo wakhtiga hoos u dhaca.

Inta lagu jiro habka wax soo saarka filimka, sifeynta waxtarka leh ayaa aad muhiim u ah.Dhammaan walxaha wasakhda ah, sida jel iyo walxaha jirka, waa in meesha laga saaraa.Sababtoo ah walxahan qashinka ah waxay keeni karaan ilmo, abuur nooc ka mid ah cilladaha aan caadiga ahayn dusha filimka.Sifeynta tayada leh ee habka wax soo saarka filimka polyester-ka ee joogtada ah waxay yeelan kartaa dhowr cawaaqib xumo, sida isbeddellada shaandhada soo noqnoqda, hoos u dhaca wax soo saarka, tayada alaabta oo hooseysa.

Si looga fogaado arrimahan, waxaa muhiim ah in la maalgeliyo nidaamyada sifeynta tayada sare leh oo si wax ku ool ah uga saari kara walxaha iyo wasakhda habka wax soo saarka.Dayactirka joogtada ah iyo la socodka nidaamka sifaynta ayaa sidoo kale gacan ka geysan kara kor u qaadida wax ku oolnimada iyo yaraynta baahida isbeddelka shaandhada joogtada ah.

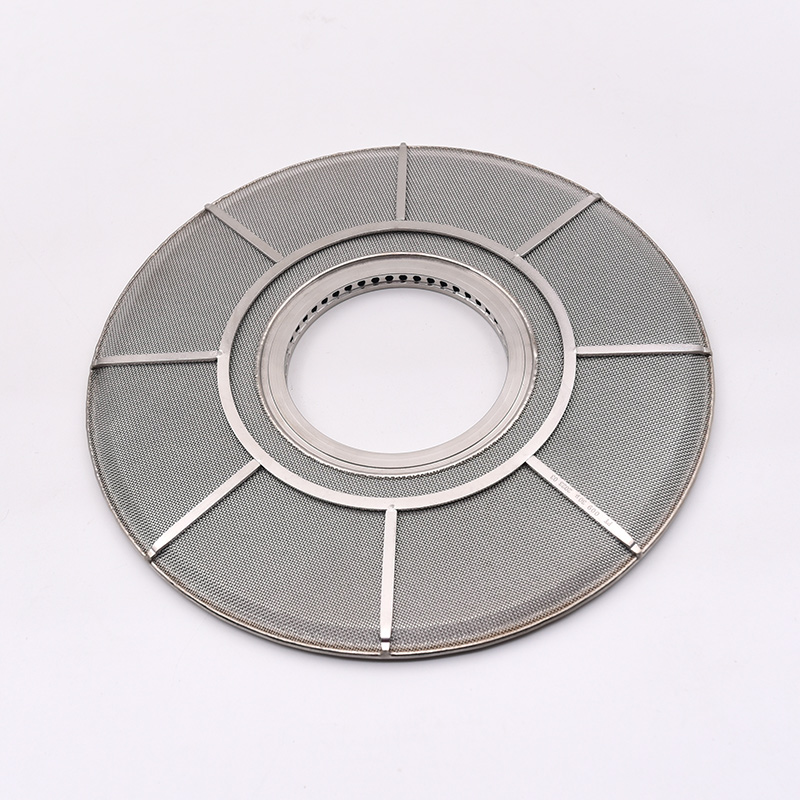

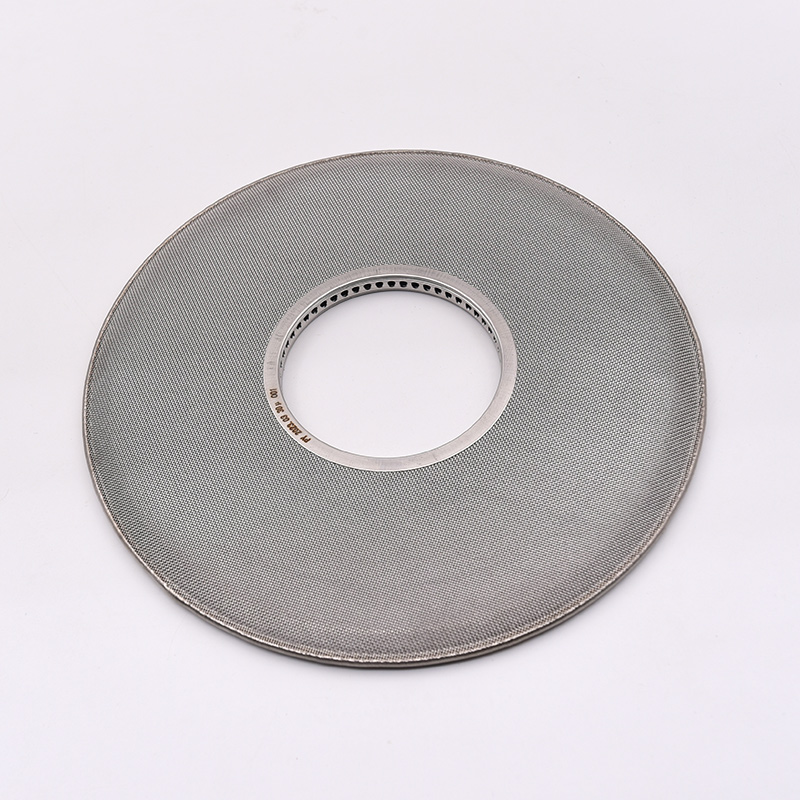

Shaandhooyinka caleenta caleentu waa alaabo si fiican u horumarsan ka dib markii aanu u jilicsanahay inaanu horumarino oo aanu ku horumarinayno sanado badan anagoo adeegsanayna qalab alxan oo heersare ah iyo habka.Waxay leedahay sifooyinka caabbinta cadaadiska sare & heerkulka, daxalka kiimikada;iyo faaruqinta wanaagsan, awoodda xajinta wasakhda weyn, waxqabad la isku halayn karo iyo cimri dheer oo leh xoog sare, adkeysi, iska caabin saameyn aad u wanaagsan, waxaana si isdaba joog ah loo isticmaali karaa nadiifinta ka dib.Waxaa inta badan loo isticmaalaa sifaynta polymer ee khadka wax soo saarka ee BOPA, BOPET, iyo BOPP, si meesha looga saaro jel polymer, wakiilka xinjirowga, kicinta, iyo wasakh kale oo adag.Shaandhooyinka discs ayaa si ballaaran loogu dabaqaa warshadaha filimka, polymer polyester, spinning, alaabta baakadaha, balaastikada injineernimada, saliidda, kiimikada iyo kuwa kale.

Tilmaamaha Farsamada

Cadaadiska shaqada:≤31.7MPa

Heerkulka shaqada:≤300℃

Mugdi dhexdhexaad ah:≤260Pa.s

Kala duwanaanshaha cadaadiska la oggol yahay:≤10Mpa

Nooca:

Nooca alxanka giraanta dhexe (xarun adag)

Nooca giraanta dhexe (hub jilicsan)

Qalabka warbaahinta:

Fiber-lakab-lakab ah oo aan-lakab ah lahayn, silig bir-lakab ah oo badan, budo bir ah oo sinteed

Heerka sifaynta (βx≥75):5,7,10,15,20,25,30,40,60,80,100μm

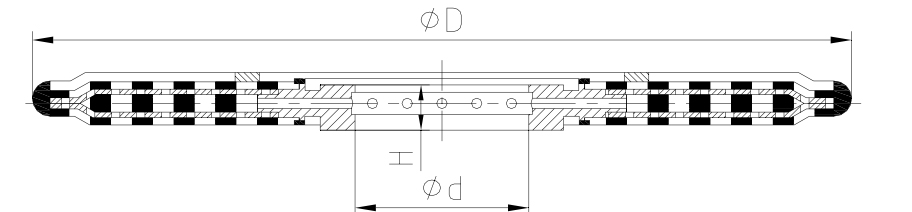

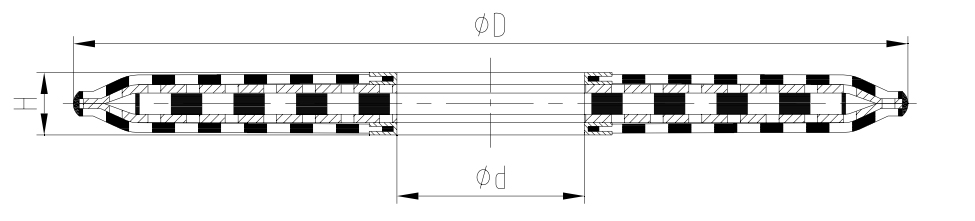

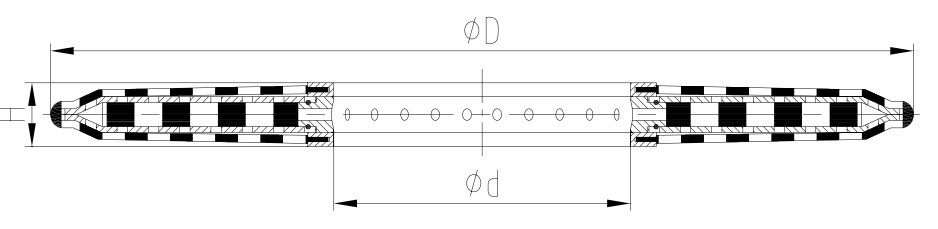

Habaynta & Cabbirada

| REF.MAYA | ΦD (mm) | Φd (mm) | H (mm) | Goobta shaandhaynta (㎡) | Ogow |

| FTD-R | Φ304.8 | Φ85 | 6.5 | 0.12 | 12 inji |

| FTD-S/233/234 | Φ304.8 | Φ63.5 | 6.5 | 0.13 | 12 inji |

| FTD-133 | Φ254 | Φ85 | 6.5 | 0.08 | 10 inch |

| FTD-179/179A/179B/179F | Φ177.8 | Φ47.6 | 6.5 | 0.04 | 7 inji |

| FTD179G | Φ254 | Φ47.6 | 7.2 | 0.082 | 10 inch |

| FTD-195/195C | Φ304.8 | Φ85 | 7 | 0.12 | 12 inji |

| FTD-195A | Φ181 | Φ85 | 8 | 0.036 | |

| FTD-195B | Φ304.8 | Φ85 | 8 | 0.12 | 12 inji |

| FTD-195H | Φ304.8 | Φ85 | 7.5 | 0.12 | 12 inji |

| FTD-195H1 | Φ297.18 | Φ85 | 7.5 | 0.11 | |

| FTD-195H2/195H3 | Φ297.18 | Φ85 | 7.8 | 0.11 | |

| FTD-199/200 | Φ222.3 | Φ63.5 | 6.5 | 0.064 | |

| FTD-202 | Φ304.8 | Φ63.5 | 7 | 0.13 | 12 inji |

| FTD-224/224A | Φ152.4 | Φ38.2 | 6.5 | 0.032 | 6 inji |

| FTD-266 | Φ177.8 | Φ85 | 6.5 | 0.029 | 7 inji |

| REF.MAYA | ΦD (mm) | Φd (mm) | H (mm) | Goobta shaandhaynta (㎡) | Ogow |

| FTD-P/J | Φ177.8 | Φ47.6 | 6 | 0.04 | 7 inji |

| FTD-Q | Φ177.8 | Φ63.5 | 6 | 0.04 | 7 inji |

| FTD-83 | Φ222.3 | Φ63.5 | 6.5 | 0.064 | |

| FTD-146 | Φ177.8 | Φ38.2 | 6 | 0.043 | 7 inji |

| FTD-167 | Φ304.8 | Φ63.5 | 5.5 | 0.13 | 12 inji |

| FTD-223 | Φ152.4 | Φ38.2 | 6.5 | 0.033 | 6 inji |

| FTD-261 | Φ222.2 | Φ63.5 | 6.8 | 0.06 | |

| FTD-264 | Φ304.8 | Φ85 | 6.2 | 0.12 | 12 inji |

| REF.NO | ΦD (mm) | Φd (mm) | H (mm) | Goobta shaandhaynta (㎡) | Ogow |

| FTD-164/164A/164B/164C | Φ177.8 | Φ47.6 | 10.5 | 0.04 | 7 inji |

| FTD-165 | Φ177.8 | Φ47.6 | 10.5 | 0.04 | 7 inji |

| FTD-248/248A/248B | Φ304.8 | Φ85 | 6.5 | 0.12 | 12 inji |

| FTD-248C | Φ304.8 | Φ63.5 | 6.1 | 0.13 | 12 inji |

| FTD-256 | Φ177.8 | Φ47.4 | 7.7 | 0.05 | 7 inji |

| FTD-256A/256B | Φ177.8 | Φ47.6 | 7.7 | 0.05 | 7 inji |

| FTD-257 | Φ304.8 | Φ63.9 | 7.7 | 0.14 | 12 inji |

| FTD-263 | Φ290 | Φ63.9 | 7.7 | 0.11 |