Nidaamka sifaynta ee shaandhaynta Polymerka dhalaalay

Nidaamka Sifeynta Polymer-ka dhalaalay

Nidaamka shaandhaynta polymer-ka dhalaalaysa ayaa lama huraan u ah codsiyo badan oo polymers lagu farsameeyo ama la isticmaalo, sida wax soo saarka PET/PA/PP polymer industry, pre-polymerizaton, polymerization final, fiber yarn, fiilada polyester staple fiber spinning, filimada BOPET/BOPP , ama xuubabka.Nidaamkani waxa uu caawiyaa in uu ka saaro wasakhda, wasakhowga, iyo walxaha saameeya viscosity-ka ee polymer-ka dhalaalay, isaga oo hubinaya tayada iyo joogtaynta badeecada ugu dambeysa.

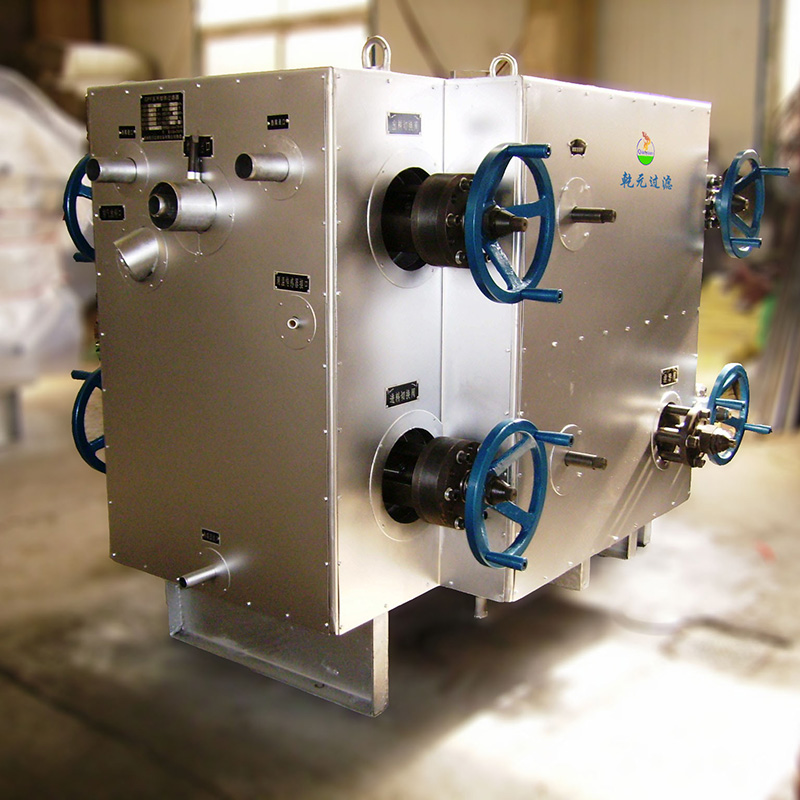

Si loo hagaajiyo tayada polymer dhalaalaysa oo loo dheereeyo nolosha adeegga qaybaha baakadka lafdhabarta, filter dhalaalid joogto ah (CPF) ayaa lagu rakibay tuubada dhalaalka ee ugu weyn.Waxay ka saari kartaa walxaha wasakhda farsamada leh dhexroorka ka weyn 20-15μm ee dhalaalka, iyo sidoo kale waxay leedahay shaqada isku mid ah dhalaalka.Guud ahaan nidaamka sifaynta waxa uu ka kooban yahay laba qol oo shaandhada, iyo valves saddex geesood ah waxay ku xidhan yihiin dhuumaha dhalaalay.Tuubooyinka saddex-geesoodka ah ayaa la beddeli karaa xilliyo si loogu beddelo isticmaalka qolalka shaandhada si loo hubiyo shaandhaynta joogtada ah.Guryaha qolka shaandhada waxaa lagu tuuray hal gabal oo leh bir aan lahayn.Shaandheeyaha aagga weyn wuxuu ka kooban yahay walxo shaandhada shumaca oo la farxo.Cunsurka shaandhada shumaca waxa taageera dhululubo xudun ah oo godadka leh, lakabka sarena waxa lagu qalabeeyaa mesh bir ah oo ka kooban hal ama lakabyo badan ama saxanka budada birta ah ee lakabyada badan leh iyo mesh bir ah oo lakabyo badan leh iyo fiilooyinka silig birta ah, iwm. Heerka sifaynta kala duwan kaas oo ku salaysan shuruudaha alaabta kama dambaysta ah.

Guud ahaan waxaa jira noocyo kala duwan oo nidaamka sifaynta, sida Horizontal sifaynta joogtada ah, nidaamka sifaynta joogtada ah ee toosan.Tusaale ahaan, inta lagu guda jiro geeddi-socodyada chips-ka PET, nooca shaandhada tooska ah ee nooca shumaca ayaa caadi ahaan la soo jeediyaa, kaas oo leh aag sifaynta 0.5㎡ halkii ubucda shumaca.Waxa jira qaabayn caadi ah oo la isticmaalo oo ah 2, 3, ama 4 cores shumac ah, oo u dhiganta meelaha sifaynta ee 1, 1.5, ama 2㎡, iyo awoodaha sifaynta dhalaalka ee u dhigma waa 150, 225, 300 kg/h.Nidaamka sifaynta tooska ah wuxuu leeyahay cabbir weyn iyo hawlgal kakan, laakiin wuxuu leeyahay faa'iidooyin badan marka loo eego habka geeddi-socodka: (1) Waxay leedahay awood kulayl badan, kala duwanaansho heerkul yar oo dhalaalaysa, iyo aag dhintay ma jiro marka alaabtu socoto.(2) Qaab dhismeedka jaakada dahaarka waa macquul, heerkulkuna waa lebis.(3) Way ku habboon tahay in kor loo qaado xudunta shaandhada marka la beddelo shaandhada.

Kala duwanaanshaha cadaadiska ka hor iyo ka dib shaandhada cusub ee la isticmaalo ayaa hooseeya.Marka uu wakhtiga isticmaalka bato, shaandhaynta godadka dhexdhexaadka ah ayaa si tartiib tartiib ah u xirma.Marka kala duwanaanshaha cadaadiska uu gaaro qiimaha dejinta, tusaale ahaan, sida chips-yada PET, guud ahaan jaantusku waa qiyaastii 5-7MPa, qolka shaandhada waa in la beddelaa.Marka farqiga cadaadiska la oggol yahay uu dhaafo, shabagga shaandhada ayaa laga yaabaa in la leexiyo, cabbirka meshku wuu kordhaa, saxnaanta sifaynta ayaa hoos u dhacda ilaa dhexdhexaadiyaha shaandhada uu dillaaco.Xudunta filtarka la beddelo waa in la nadiifiyaa ka hor inta aan dib loo isticmaalin.Cadaadiska saameeynta waxaa si fiican u go'aamiya tijaabada "tijaabada xumbo", laakiin sidoo kale waxaa lagu qiimeyn karaa iyadoo lagu saleynayo kala duwanaanshaha cadaadiska ka hor iyo ka dib shaandhada cusub ee la beddelay.Guud ahaan, marka shaandhada shumaca la dillaaco ama la nadiifiyo 10-20 jeer, waa inaan mar dambe la isticmaalin.

Tusaale ahaan, filtarrada taxanaha ah ee Barmag NSF, waxaa lagu kululeeyaa uumiga Biphenyl ee jaakada, laakiin heerkulka dareeraha wareejinta kulaylku waa inuusan dhaafin 319 ℃, iyo cadaadiska ugu badan ee Biphenyl waa 0.25MPa.Cadaadiska ugu badan ee naqshadeynta qolka shaandhada waa 25MPa.Cadaadiska ugu badan ee la oggol yahay ka hor iyo ka dib shaandhada waa 10MPa.

Qiyaasta Farsamada

| Qaabka | L | B | H | H1 | H2 | FIX(H3) | Meesha laga soo galo&DN(Φ/) | Aagga shaandhaynta (m2) | Barta Iskoolada lagu dabaqi karo (Φ/) | Heerka socodka Naqshadeysan (kg/saacaddii) | Guryaha kala shaandhaynta | Kala shaandhaynta Cunsurka | Wadarta Miisaanka (kg) |

| PF2T-0.5B | 900 | 1050 | 1350 | Sida goobta macaamiisha | 2200 | 22 | 2x0.5 | 65 | 40-80 | Φ158x565 | Φ35x425x4 | 660 | |

| PF2T-1.05B | 900 | 1050 | 1350 | 2200 | 30 | 2x1.05 | 90 | 100-180 | Φ172x600 | Φ35x425x7 | 690 | ||

| PF2T-1.26B | 900 | 1050 | 1390 | 2240 | 30 | 2x1.26 | 105 | 150-220 | Φ178x640 | Φ35x485x7 | 770 | ||

| PF2T-1.8B | 950 | 1140 | 1390 | 2240 | 40 | 2x1.8 | 120 | 220-320 | Φ235x620 | Φ35x425x12 | 980 | ||

| PF2T-1.95B | 950 | 1140 | 1390 | 2240 | 40 | 2x1.95 | 130 | 250-350 | Φ235x620 | Φ35x425x13 | 990 | ||

| PF2T-2.34B | 1030 | 1200 | 1430 | 2330 | 40 | 2x2.34 | 135 | 330-420 | Φ235x690 | Φ35x485x13 | 1290 | ||

| PF2T-2.7B | 1150 | 1200 | 1440 | 2350 | 50 | 2x2.7 | 150 | 400-500 | Φ260x690 | Φ35x485x15 | 1320 | ||

| PF2T-3.5B | 1150 | 1250 | 1440 | 2350 | 50 | 2x3.5 | 160 | 500-650 | Φ285x695 | Φ35x485x19 | 1450 | ||

| PF2T-4.0B | 1150 | 1250 | 1500 | 2400 | 50 | 2x4.0 | 170 | 600-750 | Φ285x735 | Φ35x525x19 | 1500 | ||

| PF2T-4.5B | 1150 | 1250 | 1550 | 2400 | 50 | 2x4.5 | 180 | 650-900 | Φ285x785 | Φ35x575x19 | 1550 | ||

| PF2T-5.5B | 1200 | 1300 | 1500 | 2350 | 50 | 2x5.5 | 190 | 800-1000 | Φ350x755 | Φ50x500x15 | 1650 | ||