Warshadaha fiber kiimikaad iyo filimaanta, polymer dhalaalka loo isticmaalo wax soo saarka inta badan waxa ku jira wasakh farsamo iyo qaybo jel ah oo aan milmin.Sidaa darteed, waxaa lagama maarmaan ah in la shaandheeyo polymer dhalaalka iyadoo la adeegsanayo agabka sida filtarka baakadka, silig mesh, filter shumaca, caleenta caleen ka hor inta aan la wareejin ama soo saarista filimada si meesha looga saaro wasakhda loona wanaajiyo waxqabadka wareegtada ama wax soo saarka filimada.Tani waxay sidoo kale dheereyn kartaa cimriga qaybaha.

Warshadaha fiber kiimikaad iyo filimaanta, polymer dhalaalka loo isticmaalo wax soo saarka inta badan waxa ku jira wasakh farsamo iyo qaybo jel ah oo aan milmin.Sidaa darteed, waxaa lagama maarmaan ah in la shaandheeyo polymer dhalaalka iyadoo la adeegsanayo agabka sida filtarka baakadka, silig mesh, filter shumaca, caleenta caleen ka hor inta aan la wareejin ama soo saarista filimada si meesha looga saaro wasakhda loona wanaajiyo waxqabadka wareegtada ama wax soo saarka filimada.Tani waxay sidoo kale dheereyn kartaa cimriga qaybaha.

Inta lagu guda jiro wareegga-cadaadiska sare ama habka wax soo saarka filimka, lakabka shaandheynta wuxuu abuuri karaa iska caabin sare, taasoo keenaysa kuleyl la'aan iyo kororka heerkulka polymer dhalaalka.Tani waxay kaa caawinaysaa in si fiican loo qaso polymer dhalaalaysa iyo hagaajinta sifooyinka rheological.

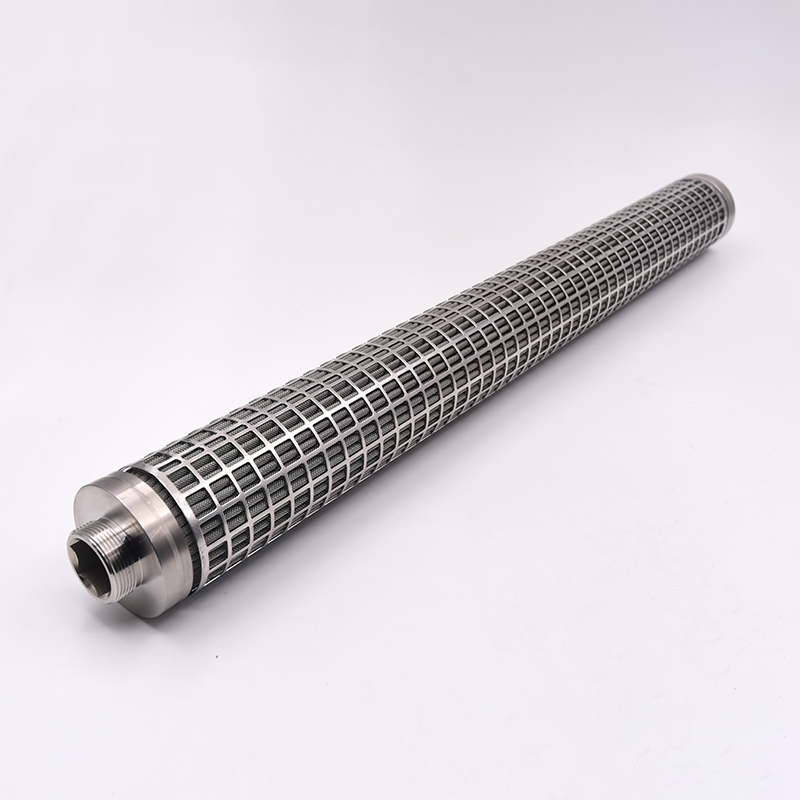

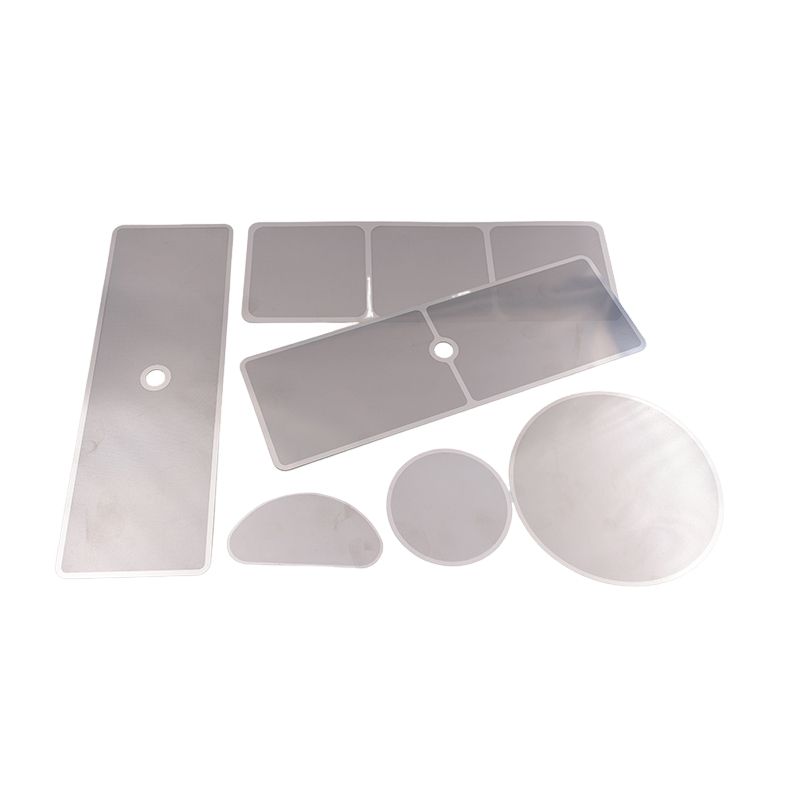

Si loo wanaajiyo tayada duubista ama filimku dhalaaliyaa polymer oo loo kordhiyo cimriga qaybaha wareegta ama saxannada caleenta, nidaamka sifaynta dhalaalaysa ee joogtada ah (pre-shaandhaynta) ayaa lagu rakibi karaa dhuumaha dhalaalay.Shaandheeyahani waxa uu ka saari karaa qurubyada waaweyn iyo wasakhda farsamo ee dhalaalka waxana ay hubisaa in si fiican oo isku mid ah loo qaso dhalaalka.Nidaamka sifaynta wuxuu ka kooban yahay laba qol oo shaandhaynta iyo waalka saddex-geesoodka ah ee ku xidha dhuumaha dhalaalay.Waalka saddex-geesoodka ah waxa loo beddelan karaa xilliyo si uu u kala beddelo qolalka shaandhaynta, iyada oo la hubinayo sifaynta joogtada ah.Guryaha qolalka shaandhaynta waxaa laga tuuray birta aan fiicnayn.Nidaamka sifaynta aagga-weyn wuxuu ka kooban yahay filtarrada shumacyo badan.Shamaca filtarrada waxaa taageera dhululubada xudunta u ah dalool waxayna leeyihiin hal ama dhowr lakab oo meshes bir ah oo tolsan ama saxanada budada birta ah ee sinteed ee lakabka sare.

Waxaan ku siin karnaa qaabab kala duwan oo ah filtar baakidh, silig mesh, filtarka shumaca iyo saxannada caleen ee cabbirro kala duwan.Heerka sifaynta iyo walxaha la isticmaalo waxaa loo habayn karaa iyadoo loo eegayo shuruudaha macaamiisha.Waxaan soo saareynaa ciid bir ah oo leh cuntooyin kala duwan oo loogu talagalay isticmaalka gudaha baakidhka lafdhabarta ee khadka fiilada kiimikada, sida polyester iyo naylon.Waxaan bixin karnaa ciid bir ah oo cabbirro mesh kala duwan ah, sida 10/20, 20/30, 30/40, 40/60, 60/80, 80/100, 100/120, iyo 120/170 meshes.

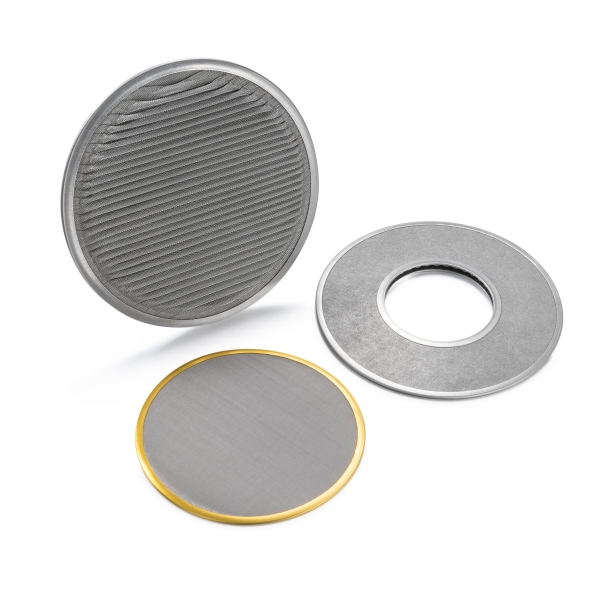

Soo saarista filimka polyamide ee jihada ah (BOPA), filimka polyester-ka (BOPET), iyo filimka polyolefin-ka ee jihada (BOPP), waa lagama maarmaan in la isticmaalo filtarrada disc si loo saaro jel, walxaha lagu daro, kicinta, iyo wasakhda kale ee adag ee polymers-ka. .Waxaan ku siin karnaa saxanooyin caleen ah oo cabbirro kala duwan leh iyo heerka shaandhaynta oo laga sameeyay agabyo kala duwan, sida dareemada fiber-ka-soo-baxa ah ee birta-lakabka ah, meshes-dahaarka-lakabka badan ee birta-daaqadaha ah, ama budada birta ah ee miiray.